Parts of your future car could be made from olive trees

Discarded branches, twigs and foliage could help reduce plastic use

Olive trees bear a versatile fruit that is used as oils, as a snack, and in thousands of recipes. But harvest time generates significant waste.

Ford explored using this discarded foliage for more sustainable auto parts. Engineers produced prototype footrests and parts of the boot area.

The trial was conducted as part of the COMPOlive project that is committed to delivering environmental change in olive production, using biocomposites instead of plastic, and supporting the circular economy.

The waste came from olive groves in Andalusia, Spain, the region with the highest production of olive oil in the world.

Avoiding burning the waste can support cleaner air in the local area.

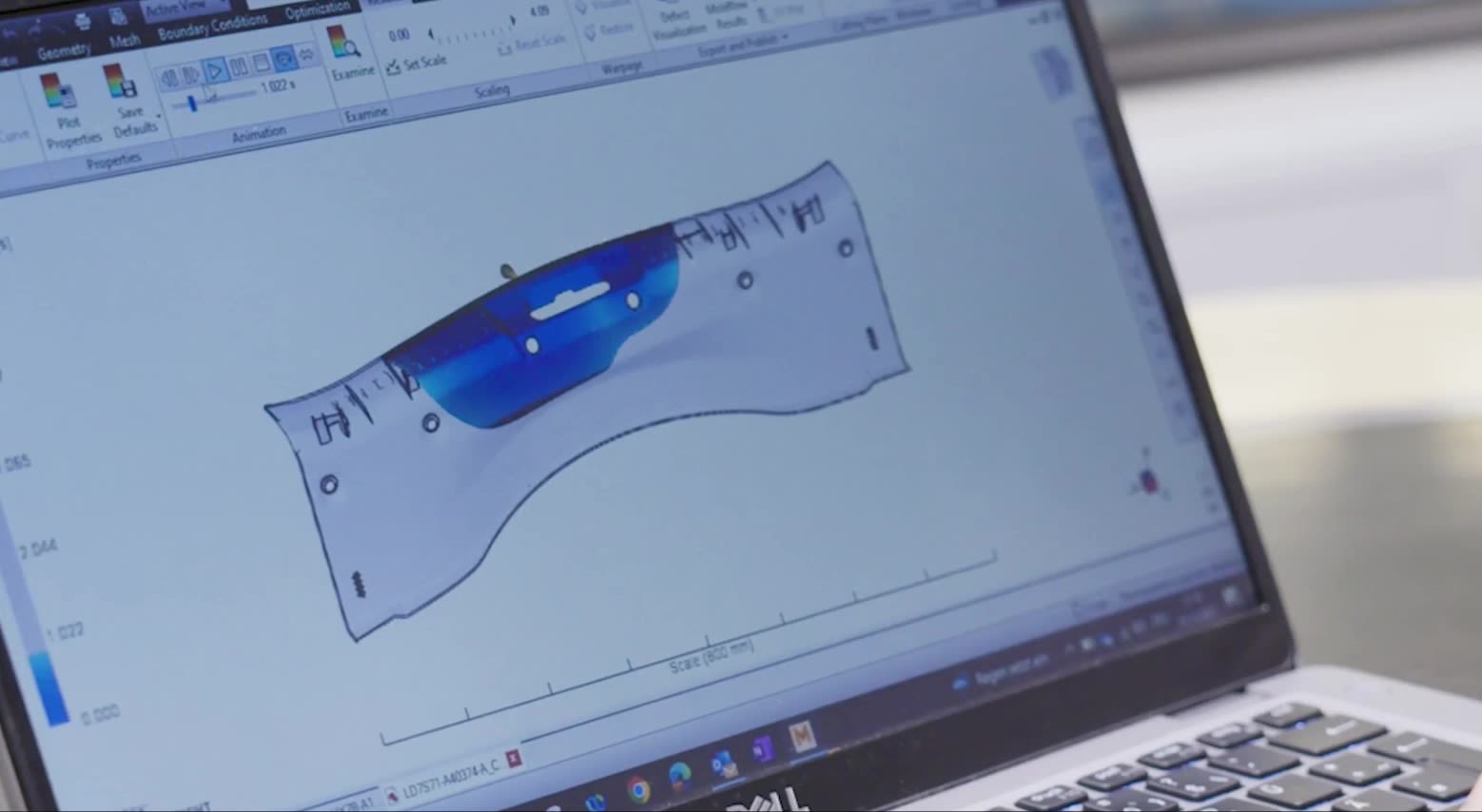

First, engineers at Ford’s European headquarters in Cologne, Germany, used clever simulation technology to test the usability of the olive tree waste.

Satisfied with the durability, strength, and mouldability of the material, they began creating prototype parts.

They combined the waste with recycled plastic – using 40 per cent fibres and 60 per cent recycled polypropylene plastic.

So that less plastic was needed.

This biocomposite material was heated and injected into closed metal moulds.

Once cooled and hardened, it was ready for use.

"At Ford, we’re always looking for ways to become more sustainable, and sometimes inspiration can strike from the most unlikely places.

In using the waste from olive trees, we have been able to substitute a significant amount of petroleum-based raw material in the interior parts. The sustainable fibres create a unique surface appearance and would be directly visible to our customers."

Inga Wehmeyer, project lead, Ford

Ford is now evaluating the process for wider implementation.

So that waste from olive trees could play a part in manufacturing the electric vehicles of the future.